Automatic Case Making Machine

-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Zhejiang

-

Validity to:

Long-term effective

-

Last update:

2017-11-27 18:48

-

Browse the number:

159

+

Zhejiang Zhengrun Machinery Co., Ltd.

- Contactaixin:

Mr. Mark(Mr.)

-

Email:

telephone:

phone:

-

Arrea:

Zhejiang

Address:No. 256, Haize Road, Binhai New Area, Pingyang, Wenzhou, Zhejiang, China 325200

- Website:

+

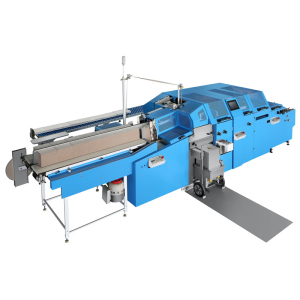

CM540A Automatic case maker

Usage:

Automatic case maker adopts automatic paper feeding system and automatic cardboard positioning device; there are features of accurate and quick positioning, and beautiful finished products etc. It is used to make perfect book covers, notebook covers, calendars, hanging calendars, files and irregular cases etc.

Features:

1. The feeder in this machine adopts back-push feeding system, which is controlled pneumatically, and its structure is simple and reasonable.

2. The width between stacker and feeding table is adjusted concentrically in the centre. The operation is very easy without error.

3. New designed copper scraper cooperates with the glue roller more compactly, effectively avoiding paper winding. And it is much more durable.

4. Adopt imported ultrasonic paper tester device, simple operation which can keep two pieces of layered paper from entering into the machine at the same time.

5. The cardboard feeding table is controlled by linear guide line and servo motor, its location is correct and quick.

6. In the cardboard feeding table, the machine can automatically stop when lack of paper to reduce rejection rate.

7. Conveyor belt is equipped with a powerful vacuum fan to keep the paper without any movement.

8. Paper feeding and positioning system adopts imported high-precise photoelectric control device to make the paper and cardboard location more accurate.

9. The folding unit adopts servo motor, no displacement and no scratches.

10. Pneumatic pressure control for folding, concentric shaft adjustment for trimming, easy to operate; it also adopts a new technology on the folding way which solves the problem of irregular covers.

11. The whole machine adopts PLC control, featuring in simple operation. The troubles are displayed directly on the screen, which helps the operator easily remove them.

12. Low electricity consumption, low noisy and easy adjustment.

Production Flow:

Product Sample:

Main Technical Parameters:

Remark:

1. The Max. and Min. sizes of cases are subjected to the size and the quality of the paper.

2. The speed depends on the size of cases

3. We don't provide air compressor.

Usage:

Automatic case maker adopts automatic paper feeding system and automatic cardboard positioning device; there are features of accurate and quick positioning, and beautiful finished products etc. It is used to make perfect book covers, notebook covers, calendars, hanging calendars, files and irregular cases etc.

Features:

1. The feeder in this machine adopts back-push feeding system, which is controlled pneumatically, and its structure is simple and reasonable.

2. The width between stacker and feeding table is adjusted concentrically in the centre. The operation is very easy without error.

3. New designed copper scraper cooperates with the glue roller more compactly, effectively avoiding paper winding. And it is much more durable.

4. Adopt imported ultrasonic paper tester device, simple operation which can keep two pieces of layered paper from entering into the machine at the same time.

5. The cardboard feeding table is controlled by linear guide line and servo motor, its location is correct and quick.

6. In the cardboard feeding table, the machine can automatically stop when lack of paper to reduce rejection rate.

7. Conveyor belt is equipped with a powerful vacuum fan to keep the paper without any movement.

8. Paper feeding and positioning system adopts imported high-precise photoelectric control device to make the paper and cardboard location more accurate.

9. The folding unit adopts servo motor, no displacement and no scratches.

10. Pneumatic pressure control for folding, concentric shaft adjustment for trimming, easy to operate; it also adopts a new technology on the folding way which solves the problem of irregular covers.

11. The whole machine adopts PLC control, featuring in simple operation. The troubles are displayed directly on the screen, which helps the operator easily remove them.

12. Low electricity consumption, low noisy and easy adjustment.

Production Flow:

Product Sample:

Main Technical Parameters:

| Model | CM540A | |

| 1 | Case size(A×B) | MIN: 100×200mm MAX: 540×1000mm |

| 2 | Paper size(A×B) | MIN: 130×230mm MAX: 570×1030mm |

| 3 | Paper thickness | 100~200g/m2 |

| 4 | Cardboard thickness(T) | 1~3mm |

| 5 | Min. spine size (S) | 10mm |

| 6 | Folded paper size(R) | 10~18mm |

| 7 | Max. quantity of cardboard | 6pieces |

| 8 | Precision | ±0.50mm |

| 9 | Production speed | <=25sheets/min |

| 10 | Power | 11kw/380v 3phase |

| 11 | Air supply | 10L/min 0.6MPa |

| 12 | Machine weight | 3900kg |

| 13 | Machine dimension (L×W×H) | L8500×W2300×H1700mm |

1. The Max. and Min. sizes of cases are subjected to the size and the quality of the paper.

2. The speed depends on the size of cases

3. We don't provide air compressor.