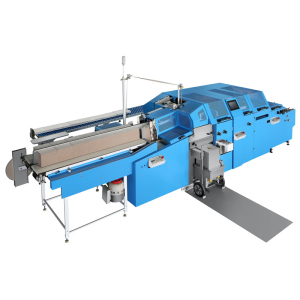

Fully Automatic Rigid Box Making Machine

-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Zhejiang

-

Validity to:

Long-term effective

-

Last update:

2017-12-26 09:16

-

Browse the number:

168

+

Zhejiang Zhengrun Machinery Co., Ltd.

- Contactaixin:

Mr. Mark(Mr.)

-

Email:

telephone:

phone:

-

Arrea:

Zhejiang

Address:No. 256, Haize Road, Binhai New Area, Pingyang, Wenzhou, Zhejiang, China 325200

- Website:

+

RB185 Automatic rigid box maker

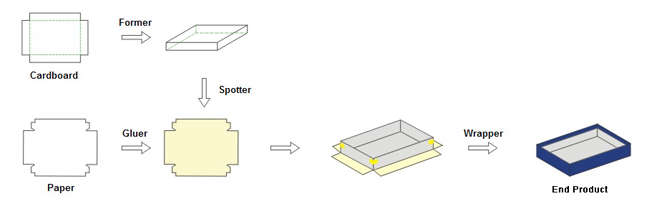

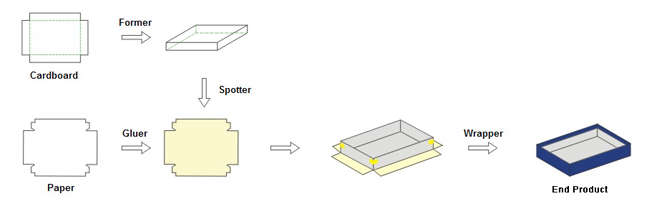

Automatic Rigid Box maker is a good equipment for making high-grade covered boxes for its fine design, reliable performances and international advanced technologies. It employs PLC, photoelectric detector system, hydraulic rectifying system, HMI to automatically finish feeding and gluing paper, conveying cardboard, forming and pasting four angles of cardboard, positioning, and forming box in one time. It is applicable to make high-grade boxes for phones, shoes, cosmetics, shirts, moon cakes, liquors, cigarettes, tea, etc.

Features:

1. New servo controlled post sucked paper feeder.

2. Automatic circulation, mixing and gluing system for hot-melting gel. (Optional device: glue viscosity meter)

3. Hot-melting adhesives paper-gluing automatic conveying, slitter, and finish pasting the cardboard inner box's four angles in one process.

4. The vacuum fan under the conveyer belt can keep the glued paper from deviating.

5. The glued paper and cardboard inner box employ hydraulic web guiding device to spot correctly.

6. The box-forming unit can automatically collect boxes and deliver them to the forming unit according to the boxes conveyed on the conveyer belt.

7. It adopts new design of servo and pneumatic control structure which can continually delivery boxes, wrap sides, fold ears and paper sides and form in one process.

8. The whole machine employs PLC, photoelectric tracking system and touch screen man-machine interface to form boxes automatically in one process.

9. It can automatically diagnose the troubles and alarm accordingly.

Main Technical Parameters:

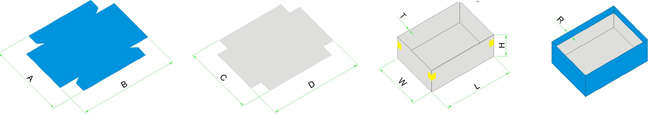

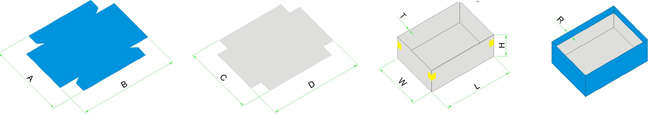

The corresponding relationship between the parameters:

W+2H-4T≤C(Max) L+2H-4T≤D(Max)

A(Min)≤W+2H+2T+2R≤A(Max) B(Min)≤L+2H+2T+2R≤B(Max)

Paper type:

1. The max and mini sizes of the boxes are subjected to those of the paper and the quality of the paper.

2. The speed of the machine depends on the sizes of the boxes.

3. We don't provide air compressor.

Automatic Rigid Box maker is a good equipment for making high-grade covered boxes for its fine design, reliable performances and international advanced technologies. It employs PLC, photoelectric detector system, hydraulic rectifying system, HMI to automatically finish feeding and gluing paper, conveying cardboard, forming and pasting four angles of cardboard, positioning, and forming box in one time. It is applicable to make high-grade boxes for phones, shoes, cosmetics, shirts, moon cakes, liquors, cigarettes, tea, etc.

Features:

1. New servo controlled post sucked paper feeder.

2. Automatic circulation, mixing and gluing system for hot-melting gel. (Optional device: glue viscosity meter)

3. Hot-melting adhesives paper-gluing automatic conveying, slitter, and finish pasting the cardboard inner box's four angles in one process.

4. The vacuum fan under the conveyer belt can keep the glued paper from deviating.

5. The glued paper and cardboard inner box employ hydraulic web guiding device to spot correctly.

6. The box-forming unit can automatically collect boxes and deliver them to the forming unit according to the boxes conveyed on the conveyer belt.

7. It adopts new design of servo and pneumatic control structure which can continually delivery boxes, wrap sides, fold ears and paper sides and form in one process.

8. The whole machine employs PLC, photoelectric tracking system and touch screen man-machine interface to form boxes automatically in one process.

9. It can automatically diagnose the troubles and alarm accordingly.

Main Technical Parameters:

The corresponding relationship between the parameters:

W+2H-4T≤C(Max) L+2H-4T≤D(Max)

A(Min)≤W+2H+2T+2R≤A(Max) B(Min)≤L+2H+2T+2R≤B(Max)

| Model | RB185 | |

| 1 | Paper size(A×B) | Min.120×250mm Max.610×850mm |

| 2 | Box size(W×L) | Min. 50×100mm Max.400×600mm |

| 3 | Paper thickness | 100-200g/m2 |

| 4 | Cardboard thickness(T) | 0.8~3mm |

| 5 | Box height(H) | 12-185mm |

| 6 | Fold-in paper size(R) | 10-100mm |

| 7 | Precision | ±0.50mm |

| 8 | Speed | <=25sheets/min |

| 9 | Motor power | 17.29kw/380v 3phase |

| 10 | Heater power | 6kw |

| 11 | Machine weight | 6800kg |

| 12 | Machine dimension(L×W×H) | L7000×W4100×H3600mm |

| 13 | Paper type | 1/2/3 |

1. The max and mini sizes of the boxes are subjected to those of the paper and the quality of the paper.

2. The speed of the machine depends on the sizes of the boxes.

3. We don't provide air compressor.