Customize Alumium Honeycomb Panels for Partitions and Cleanrooms

-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Guangdong

-

Validity to:

Long-term effective

-

Last update:

2017-11-18 00:41

-

Browse the number:

105

+

- Contactaixin:

Miss Wendy(Mr.)

-

Email:

telephone:

phone:

-

Arrea:

Guangdong

Address:Jin Yong Heng, Shiling Shishan Town, Nanhai District, Foshan, Guangdong, China 528244

- Website:

+

Common Panel thickness: 6mm, 8mm, 10mm, 12mm, 15mm, 18mm, 20mm, 25mm

Skin thickness: 0.5mm, 0.6mm, 0.7mm, 0.8mm, 1.0mm

Skin Material: Alumium Alloy 3003 H24

Skin material can be different materials according to different applications, such as stainless steel, galvanized sheet, fiberglass sheet, wood, HPL laminate and etc.

Aluminum honeycomb panel is a kind of sandwich panel consisting of two aluminum plates as face panels and hexagonal aluminum honeycomb cell as core materials, bonded together by aviation-purpose glue or macromolecule lamination film. Thanks to its superb characteristic of light weight, good strength, hyper flatness, sound and heat proof, aluminum honeycombpanel has transferred from aviation industry's usage to civil application, and tends to be the most popular light weight panel, widely used in façade cladding industry, interior decoration, ceiling, partition, furniture industry, ship hull building and ship decoration, vehicle building and so on.

Specifications Available

| Length: | 200mm----13000mm |

| Width: | 200mm----- 2000mm. |

| Thickness: | 3mm----- 600mm |

| Skin Thickness: | 0.3mm-3mm |

| Color : | Granite or marble, wood grain, stone grain, silver/gold brush, mirror faced, chameleon and so on; |

Any other color or finish can be imagined by the customer.

Max Thickness: 500mm

Standard size: 1220x2440mm

Max size: 2000x12000mm

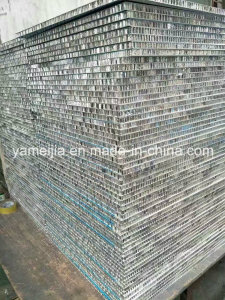

Our honeycomb panel photos

Features of aluminium honeycomb panels

Weight

One of the primary reasons for utilizing aluminum honeycomb panels is that they exhibit excellent strength-to-weight ratios compared to traditional construction materials.

Strength

The ability to configure panels with different materials allows us to create much stronger panels than one can achieve with solid structures. The skill, however, is in analyzing all of the material choices for meeting your specifications and then selecting those that will provide the most functionality at the lowest cost.

Fire Resistance

Huarui uses a number of materials that are non-combustible and self extinguishing. Most flammability ratings and building codes can be easily met with some combination of materials.

Thermal Control

Most aluminum honeycomb panels have excellent insulation properties simply due to the nature in which they are designed. Since both honeycomb and foam cores trap air between the skins, they are inherently insulating to some degree.

Sound Control

While we do not specialize in acoustical panels, we are happy to incorporate any type of sound deadening specifications into the composite panels that we design.

Impact Resistance

Impact resistance can be accounted for by adjusting the honeycomb cell size, utilizing different core materials and skins, or adding thickness to the surface material and/or core.

Moisture Resistance

All types of aluminum and plastic honeycomb cores can be used to improve water and moisture resistance, but RFP surface materials can also do the job for many applications.

Corrosion Resistance Not only can we utilize different core and surface materials to achieve resistance to weather and chemicals, but coatings can be applied for added security.

| Technical Data | ||||||||

| Panel-Thickness: | 6mm | 10mm | 15mm | 20mm | 25mm | |||

| Aluminium Cover Sheet,front side[mm] | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | |||

| Aluminium Cover Sheet,reverse side[mm] | 0.50 | 0.50 | 1.00 | 1.00 | 1.00 | |||

| Weight[kg/m2] | 4.9 | 5.3 | 6.9 | 7.2 | 7.5 | |||

| Technical Propertles: | ||||||||

| Section Modulus Z [cm³/m] | 2.5 | 4.5 | 14.00 | 19.00 | 24.00 | |||

| Rigidity E.l [kNcm2/m] | 7'100 | 21'900 | 75'500 | 139'000 | 221'700 | |||

| Aluminum Alloy skin | 3003-16 | |||||||

| Modulus of Elastlcity [N/mm2] | 70'000 | |||||||

| Tensile Strength of cover sheets [N/mm2] | Rm≥125 | |||||||

| 0.2% Proof Stress [N/mm2] | Rp02≥80 | |||||||

| Elongation(EN 485:1994) | A50≥5% | |||||||

| Temperature Resistance | -40ºC to+90ºC | |||||||

| Linear Thermal Expansion | 2.4 mm/m at 100ºC temperature difference | |||||||

| SURFACE | ||||||||

| Front skin | Continuous Coil Coating-Fluorocarbon(PVDF) | |||||||

| Gloss( initia value) | 25%-45% | |||||||

| Pencil Hardness | HB-F | |||||||

| Rear skin | Polyester based wsh coat | |||||||

| CORE | ||||||||

| Cellsize | "1/4" ,3/8",1/2" | |||||||

| Acoustical Propertles: | ||||||||

| Sound Absorption Factor | α | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | ||

| Airborne Sound Insulation Index | Rw [dB] | 21 | 21 | 22 | 23 | 25 | ||

| DIMENSIONAL TOLERANCES | ||||||||

| Thickness | ±0.2mm | |||||||

| Width | 0/+2mm | |||||||

| Length | 1000-5000mm | 0/+3mm | ||||||

| 5001-11800m | 0/+4mm | |||||||

Application of Aluminum honeycomb panels

Aluminum honeycomb panels can be used in a variety of fields including wall materials, interior decoration, ceiling, partition, furniture industry, ship hull building and ship decoration, vehicle building , lift and elevator , Train and high speed subway.

Production facility

Packaging&Delivery: Protective film on the surface of aluminum honeycomb panel, then the panel is packed in export grade polywood carton.

Delivery time:

Regular leadtime: 10-30 days

Peak season leadtime:30 working days.

Off season leadtime: 10 working days

For more information pls contact us:

website:www.al-honeycomb-panels.com

Tel: +86 (0)757 85681262-803

Mob: +86 18823286927