Transmission Line Bare Aluminum Wire 336.4 Mcm AAC

-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Henan

-

Validity to:

Long-term effective

-

Last update:

2017-10-11 05:04

-

Browse the number:

200

+

Luoyang Asian Sun Industrial Group Co., Ltd.

- Contactaixin:

Mr. Leo(Mr.)

-

Email:

telephone:

phone:

-

Arrea:

Henan

Address:Building B#18f, World Trade Center, No 258 Kaiyuan Road, Luoyang City, Henan Province, Luoyang, Henan, China 471000

- Website:

+

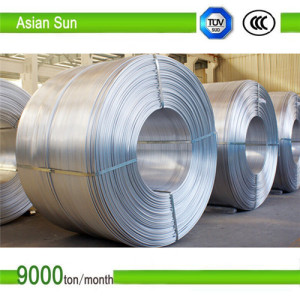

Transmission Line Bare aluminum wire 336.4 MCM AAC

Specifications

Transmission Line Bare aluminum wire 336.4 MCM AAC

1.18 years factory product

2.good feature

3.delivery fast

ACSR,AAC,AAAC,ASCSR&ACAR conductor widely used in power transmission lines with various voltage

levels.

Specification:

(1) all aluminum conductor (AAC)

(2) all aluminum alloy conductor(AAAC)

(3) aluminum conductor steel reinforced (ACSR)

(4) anti-corrosion type ACSR

(5) aluminum conductor aluminum clad steel reinforced(ACSR/AW)

(6)rear earth aluminum conductor steel reinforced(ACSR/RE)

(7)aluminum conductor aluminum alloy reinforced(ACAR)

AAAC Conductor

Are made out from aluminum-magnesiumsilicon alloy of high electrical conductivity (min 53% IACS)

containing magnesium (0.6-0.9%) & silicon (0.5-0.9%) to give it better mechanical properties after

treatment. AAAC conductors are made out of aluminum alloy 6201. AAAC conductor has a better

corrosion resistance and better strength to weight ratio and improved electrical conductivity than

ACSR conductor on equal diameter basis.

Standards:

ASTM-B232 Standard specification for Concentric-Lay-Stranded Aluminum 1350 Conductors

BS215-2 aluminum conductors steel-reinforced -For overhead power transmission

DIN48204 Steel reinforced aluminum stranded conductors

IEC209 Aluminum stranded conductor steel reinforced

Customized type available.

AAAC Technical Characteristics Based on Standard BS 3242

ACSR Technical Characteristics Based on Standard BS 215-2

Specifications

Transmission Line Bare aluminum wire 336.4 MCM AAC

1.18 years factory product

2.good feature

3.delivery fast

ACSR,AAC,AAAC,ASCSR&ACAR conductor widely used in power transmission lines with various voltage

levels.

Specification:

(1) all aluminum conductor (AAC)

(2) all aluminum alloy conductor(AAAC)

(3) aluminum conductor steel reinforced (ACSR)

(4) anti-corrosion type ACSR

(5) aluminum conductor aluminum clad steel reinforced(ACSR/AW)

(6)rear earth aluminum conductor steel reinforced(ACSR/RE)

(7)aluminum conductor aluminum alloy reinforced(ACAR)

| Code number | Area | Number of wires | Wire diameter | Conductor diameter | Linear mass | Rated strength | D.C. resistance at 20oC |

| mm2 | No. | mm | mm | kg/km | kN | Ω/km | |

| 16 | 15.9 | 7 | 1.7 | 5.1 | 43.4 | 3.02 | 1.7986 |

| 25 | 24.2 | 7 | 2.1 | 6.3 | 66.3 | 4.36 | 1.1787 |

| 35 | 34.4 | 7 | 2.5 | 7.5 | 93.9 | 6.01 | 0.8317 |

| 50 | 49.5 | 7 | 3 | 9 | 135.2 | 8.41 | 0.5776 |

| 50 | 48.3 | 19 | 1.8 | 9 | 132.9 | 8.94 | 0.5944 |

| 70 | 65.8 | 19 | 2.1 | 10.5 | 180.9 | 11.85 | 0.4367 |

| 95 | 93.3 | 19 | 2.5 | 12.5 | 256.3 | 16.32 | 0.3081 |

| 120 | 117 | 19 | 2.8 | 14 | 321.5 | 19.89 | 0.2456 |

| 150 | 147.1 | 37 | 2.25 | 15.8 | 405.7 | 26.48 | 0.196 |

| 185 | 181.6 | 37 | 2.5 | 17.5 | 500.9 | 31.78 | 0.1588 |

| 240 | 242.5 | 61 | 2.25 | 20.3 | 671.1 | 43.66 | 0.1193 |

| 300 | 299.4 | 61 | 2.5 | 22.5 | 828.5 | 52.4 | 0.0966 |

AAAC Conductor

Are made out from aluminum-magnesiumsilicon alloy of high electrical conductivity (min 53% IACS)

containing magnesium (0.6-0.9%) & silicon (0.5-0.9%) to give it better mechanical properties after

treatment. AAAC conductors are made out of aluminum alloy 6201. AAAC conductor has a better

corrosion resistance and better strength to weight ratio and improved electrical conductivity than

ACSR conductor on equal diameter basis.

Standards:

ASTM-B232 Standard specification for Concentric-Lay-Stranded Aluminum 1350 Conductors

BS215-2 aluminum conductors steel-reinforced -For overhead power transmission

DIN48204 Steel reinforced aluminum stranded conductors

IEC209 Aluminum stranded conductor steel reinforced

Customized type available.

AAAC Technical Characteristics Based on Standard BS 3242

| Code name | Nominal aluminum area | Stranding and wire diameter | Sectional area | Approx. overall diameter | Approx. mass | Calculated D.C. Resistance at 20oC |

Calculated breaking load |

| mm2 | No./mm | mm2 | mm | kg/km | Ω/km | kN | |

| ALMOND | 25 | 7/2.34 | 30.1 | 7.02 | 82 | 1.094 | 8.44 |

| CEDAR | 30 | 7/2.54 | 35.47 | 7.62 | 97 | 0.9281 | 9.94 |

| FIR | 40 | 7/2.95 | 47.84 | 8.85 | 131 | 0.688 | 13.4 |

| HAZEL | 50 | 7/3.30 | 59.87 | 9.9 | 164 | 0.5498 | 16.8 |

| OAK | 100 | 7/4.65 | 118.9 | 13.95 | 325 | 0.2769 | 33.3 |

| ASH | 150 | 19/3.48 | 180.7 | 17.4 | 497 | 0.183 | 50.65 |

| ELM | 175 | 19/3.76 | 211 | 18.8 | 580 | 0.1568 | 59.1 |

| UPAS | 300 | 37/3.53 | 362.1 | 24.71 | 997 | 0.09155 | 101.5 |

ACSR Technical Characteristics Based on Standard BS 215-2

| Code name | Nominal aluminum area | Stranding and wire diameter | Sectional area of aluminum | Total sectional area | Approx. overall diameter | Approx. mass | Calculated D.C. resistance at 20oC | Calculated breaking load | |

| Al | Steel | ||||||||

| mm2 | No./mm | mm2 | mm2 | mm | kg/km | Ω/km | kN | ||

| RABBIT | 50 | 6/3.35 | 1/3.35 | 52.88 | 61.7 | 10.05 | 214 | 0.5426 | 18.35 |

| DOG | 100 | 6/4.72 | 7/1.57 | 105 | 118.5 | 14.15 | 394 | 0.2733 | 32.7 |

| WOLF | 150 | 30/2.59 | 7/2.59 | 158.1 | 194.9 | 18.13 | 726 | 0.1828 | 69.2 |

| DINGO | 150 | 18/3.35 | 1/3.35 | 158.7 | 167.5 | 16.75 | 506 | 0.1815 | 35.7 |

| LYNX | 175 | 30/2.79 | 7/2.79 | 183.4 | 226.2 | 19.53 | 842 | 0.1576 | 79.8 |

| ZEBRA | 400 | 54/3.18 | 7/3.18 | 428.9 | 484.5 | 28.62 | 1621 | 0.0674 | 131.9 |