Automatic Poultry Equipment with Prefabricated House Construction

-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Shandong

-

Validity to:

Long-term effective

-

Last update:

2017-10-01 09:12

-

Browse the number:

153

+

Qingdao Super Herdsman Machinery Co., Ltd.

- Contactaixin:

Mr. Baojie(Mr.)

-

Email:

telephone:

phone:

-

Arrea:

Shandong

Address:N0.175, Yanqing Yiji Road, Qingdao, Shandong, China 266200

- Website:

+

About us

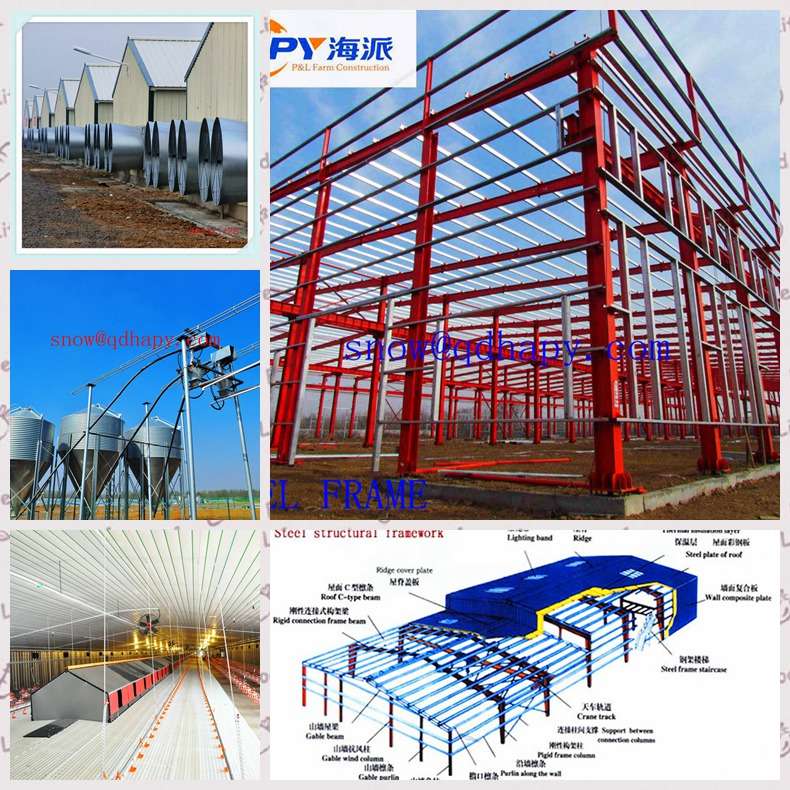

we are a leading Manufacturer of poultry husbandry equipment in China since 2009. Besides equipment , we can also do light steel poultry house construction service . Our Hapy poultry &livestock farm construction co.,ltd is one of the top 3 farm construction company in china , with more than 27 thousand m2 plant and modern processing equipment . Therefore , we know how to make the poultry shed and equipment match perfectly

Our equipments have seven main system for breeding chicken, and we can also give you suggestions about building poultry house and some related information.

1. Main feeding system

2. Broiler feed system

3. Nipple drinking system

4. Ventilation system

5. Environment control system

6. Cooling pad system

7. Spraying system

Advantages of our poultry equipment for sale:

a. Time saving&labor saving, 1 farm just need 1 worker;

b. Increasing survival rate;

c. Save feed&water;

d. Automatic controlling the raising environment;

e. Easy to operate, install, disassembly and clean;

f. 20-year service life, 12-month warranty, 0.1%-0.5% free spare parts;

1. Main feeding line system

In the main feeding line system the feed is transferred from the silo to the hopper in chicken house by auger. There is a feed sensor at the end of the main feed line which control of open and close of the motor to realize the automatic feeding.

| Silo Model | Volume | Number of Layers | Height (exclusive of foundation) | Material |

| QDSHS-01 | 4.4 m3, 2.8T | 1 | 4.1 m | Galvanized sheet |

| QDSHS-02 | 6.8 m3, 4.4T | 2 | 5 m | Galvanized sheet |

| QDSHS-03 | 9.2 m3, 5.9T | 3 | 5.9 m | Galvanized sheet |

| QDSHS-04 | 11.7 m3, 7T | 1 | 4.7 m | Galvanized sheet |

| QDSHS-05 | 16.9 m3, 10T | 2 | 5.6 m | Galvanized sheet |

| QDSHS-06 | 22.1 m3, 13T | 3 | 6.5 m | Galvanized sheet |

| QDSHS-07 | 24.5 m3, 16T | 1 | 5.8 m | Galvanized sheet |

| QDSHS-08 | 34 m3, 22T | 2 | 6.7 m | Galvanized sheet |

| QDSHS-09 | 43 m3, 28T | 3 | 7.6 m | Galvanized sheet |

|

Material description: 1. Silo roof plate and silo wall plate layer-galvanized sheets with the thickness of 1.2mm, second layer of silo wall plate-galvanized sheet with the thickness of 1.5mm. 2. Conical bottom plate-galvanized sheet with the thickness of 1.5mm, silo column- hot dip galvanizing on the surface: No. 10 channel steel, support-φ 3.6mm, 8 supports/silo. | ||||

2. Pan feeding line system

In the pan feeding system the feed sensor control the motor to open and close to realize the automatic feeding. The system consists of hopper, motor, feed pipe and auger.

| Name | Description |

| Pan feeder | 1. By sliding shutter can adjust feed amount from complete open to complete close. 2. Pan plate can be disassembled on the ground working as chick feed pan for 0-7 days old chicken. 3. V-pan plate design can reduce feed storage at pan bottom. Bird can have fresh feed every day. This design can also prevent bird from staying on the plate too long. 4. Motor: power 0.75KW voltage:380V. |

| Hopper | Capacity: 100L, raw material is hot galvanized steel, coat 120g/ m2 |

| Auger | Imported from South Africa, feed capacity is 450kg/h. |

| Delivery pipe | 4 pans/3m, diameter: ø45mm |

3. Nipple drinking line system

In modern poultry production, nipple drinkers have proven to be a reliable and hygienic solution for the supply of water. It is consisted by water front parts, drinking system, hanging system, regulator and water line end parts .

| Name | Description |

| Nipple shell | Made of high-quality engineering plastic, and the valve rod inside is made of high-quality stainless steel. |

| Valve stem | Can rotate freely at 360 degree to meet bird water demand of different period |

| Hanging system | It is easy to adjust the height and the levelness by the winch and the adjustable strip |

| Structure | Double-decked seal structure can effectively avoid wasting water and the resulting impact on the environment humidity. |

| Feeding capacity | broiler: 8-12 birds /nipple, birds in cage: 12 birds/nipple, breeder: 10 birds/nipple |

| Dosing device |

Flow rate: 10 L / h - 2.5 m3/h Working pressure :0.3bar-6bar Dosing rate: 0.02L / h - 50 L/ h Maximum working temperature: 40ºC Adjustment ratio: 0.2% to 2%(1:500-1:50) Connecting size: external thread G3/4 |

Water Level Display Height:

| Chicken Age (days) | 1-7days | 8-14days | More than 15 days |

| Water Level Height of display Tube (mm) | 50-80mm | 80-200mm | 200-350mm |

| Name | Feature |

| Motor | High efficiency and low wastage of energy. The Grade of protection is IP54 and the Insulation Grade is F. Rated power: 1.1kw, rated voltage: 380v |

| Frame | Galvanized steel sheet, steel thcikness 275g/m2,stamping forming, bottom outlet. |

| Blade | Stainless steel blade, By dynamic balance test machine, stable running and volume stability. |

| Shutters | Hot galvanized sheet forming, with automatic opening device |

| Defend net | Hot galvanized anti-rust processing. |

| Automatic opening device | Nylon and glass fiber materials, long life service. |

| Belt | Imported from Japan, long-term use without deformation. |

| Belt pulley | Hard alloy material quality by hot die casting, light material and high intensity. |

a. This system is of great importance for a chicken house, which is used for providing a most suitable growing environment for chicken.

b. The system consists of below parts: air inlet, exhaust fan, cooling pad, spraying system and panel door.

c. Cooling pad and exhaust fan combination is the most economical and effective method to lower the temperature in summer.

Exhaust fan component list:

| Name | Feature |

| Motor | High efficiency and low wastage of energy. The Grade of protection is IP54 and the Insulation Grade is F. Rated power: 1.1kw, rated voltage: 380v |

| Frame | Galvanized steel sheet, steel thcikness 275g/m2,stamping forming, bottom outlet. |

| Blade | Stainless steel blade, By dynamic balance test machine, stable running and volume stability. |

| Shutters | Hot galvanized sheet forming, with automatic opening device |

| Defend net | Hot galvanized anti-rust processing. |

| Automatic opening device | Nylon and glass fiber materials, long life service. |

| Belt | Imported from Japan, long-term use without deformation. |

| Belt pulley | Hard alloy material quality by hot die casting, light material and high intensity. |

Common FAQ :

|

1. Chicken farm net size (Length*width*height); |

| 2. Quantity of chickens in one farm; |

| 3. Weight of chickens when they're for sale in market; |

| 4. Types of chicken: broiler/breeder/layer; |

| 5. Types of breeding: on the ground/in cages; |

| 6. Chicken farm location and local climate condition such as the temperature, humidity etc. |

| 7. More information more helpful. |

We have lots of construction projects home and abroad, our sales volume in Philippine market is NO.1, we are the best and the most reliable supplier in this area, and also we are the top 3 supplier in Pakistan and Sudan. There still are projects in Dubai, Oman and other countries.

Also, our company is recruiting global agents, welcome you to join us with our utmost and warm expectation.

If you need more specific information,pls contact us ,we will provide you professional and detailed solving plans.

If you are interested in our products, pls don't hesite to contact with SNOW and I am happy to offer our high quality products with reasonable price as well as good dervice for you.

Mobile telephone :+86 17762017539