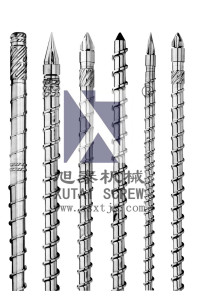

Parallel Twin Screw for PVC

-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Zhejiang

-

Validity to:

Long-term effective

-

Last update:

2017-12-12 20:52

-

Browse the number:

111

+

- Contactaixin:

Ms. Angel Chu(Mr.)

-

Email:

telephone:

phone:

-

Arrea:

Zhejiang

Address:No. 10, Road Donghou, Shantan, Jintang Town, Dinghai District, Zhoushan, Zhejiang, China 316021

- Website:

+

--Who We Are?

XuTai Machinery located in Zhejiang Province, is a professional Screw Barrel manufacturer

--What We Do?

parallel twin screw,

conical twin screw,

single extruder machine screw,

injection machine screws & barrel.

rubber machine screws & barrel.

chemical fiber machine screws & barrel.

--Why Choose Us?

1.Always Quality is the first one then prices, we have expericenced engineer and skilled worker to control products quality. We promise neither produce nor delivery any unqulified products.

2.Powerful Resource: R&D team /the biggest Raw material market source in south China /the most specialized Heating Treatment

3.Multiful service: develop screws /design and rebuild

Products Specification

Ratio (L/D):18~35 Could be designed different types according to a variety of raw material and products.

---Ф52/2, Ф60/2, Ф65/2, Ф70/2, Ф72/2, Ф75/2, Ф80/2, Ф85/2,

---Ф90/2, Ф93/2, Ф100/2,Ф105/2, Ф110/2, Ф115/2, Ф120/2,

---Ф125/2, Ф130/2, Ф140/2, Ф150/2, Ф160/2, Ф170/2, Ф180/2,

-- Ф190/2, Ф200/2, Ф250/2,

Technical Index

---Depth of Nitration Layer: 0.5-0.8mm

---Hardness of Nitration: 900-1020HV

---Fragility of Nitration: less than Grade 1

---Roughness of surface:Ra0.4

---Straightness of Screw : 0.015mm

Material of Screw

1) 38CrMoAla(JIS SCM645)

2) 42CrMoAla(SCM440)

Heat treatment:

Quenching and Tempering/ Nitriding

Proccessing:

High quality material→Heat treatment (quenching and tempering)→Rough machining→

Heat treatment (shaping)→Precision machining→Rough milling→Heat treatment (Nitride hardening)→Precision milling→Inspection→Packing and Delivery.

Our advantage:

1) more than 15 years of produce experience

2) experienced R&D team to responsible for the products

3) reply the inquiries within one day since received time

4) best after-sales service