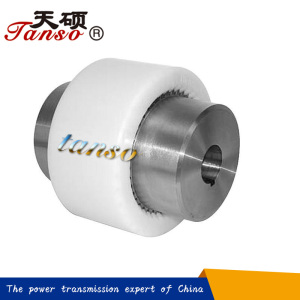

Giicl Type Curved Tooth Gear Coupling

-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Hebei

-

Validity to:

Long-term effective

-

Last update:

2017-10-22 22:25

-

Browse the number:

177

+

- Contactaixin:

Ms. Tiffany Tang(Mr.)

-

Email:

telephone:

phone:

-

Arrea:

Hebei

Address:Nancang Street, Botou City, Hebei Province 062150

- Website:

+

A gear coupling is a mechanical device for transmitting torque between two shafts that are not collinear. It consists of a flexible joint fixed to each shaft. The two joints are connected by a third shaft, called the spindle.

Each joint consists of a 1:1 gear ratio internal/external gear pair. The tooth flanks and outer diameter of the external gear are crowned to allow for angular displacement between the two gears. Mechanically, the gears are equivalent to rotating splines with modified profiles. They are called gears because of the relatively large size of the teeth.

Gear couplings and universal joints are used in similar applications. Gear couplings have higher torque densities than universal joints designed to fit a given space while universal joints induce lower vibrations. The limit on torque density in universal joints is due to the limited cross sections of the cross and yoke. The gear teeth in a gear coupling have high backlash to allow for angular misalignment. The excess backlash can contribute to vibration.

Gear couplings are generally limited to angular misalignments, i.e., the angle of the spindle relative to the axes of the connected shafts, of 4-5°. Universal joints are capable of higher misalignments.

Advantages of Tanso gear coupling

1. Lowest price based on large scale production.

2. High and stable quality level.

3. Widely used in various mechanical and hydraulic fields.

4. Compensation for axial, radial and angular misalignment.

5. Convenient axial plugging assembly.

6. No brittlement at low temperature.

7. Good slippery and frictional properties.

8. Resistance to chemical corrosion.

9. Rich experience working with big companies in this field.

II type:the seal is the whole body, the tooth spacing is smaller, the relative axial displacement is smaller,the structure is compact, the moment of inertia is small, and can be connected with the Y and J1 axis.

| Type | Nominal torque | Max speed | Bore diameter | Bore length | D | D1 | D2 | C | H | A | B | e | Mass | Moment of inertia | |

| Tn | [n] | d1,d2 | L | m | I/kg·m2 | ||||||||||

| /N·m | /r·min-1 | Y | J1 | /kg | |||||||||||

| GIICL1 | 400 | 4000 | 16,18,19 | 42 | - | 103 | 71 | 50 | 8 | 2 | 36 | 76 | 38 | 5.1 | 0.014 |

| 20,22,24 | 52 | 38 | 3 | 0.014 | |||||||||||

| 25,28 | 62 | 44 | 3.1 | 0.014 | |||||||||||

| 30,32,35 | 82 | 60 | 3.6 | 0.015 | |||||||||||

| GIICL2 | 710 | 4000 | 20,22,24 | 52 | 38 | 115 | 83 | 60 | 8 | 2 | 42 | 88 | 42 | 4.9 | 0.023 |

| 25,28 | 62 | 44 | 4.5 | 0.022 | |||||||||||

| 30,32,35,38 | 82 | 60 | 5.1 | 0.024 | |||||||||||

| 40,42,45 | 112 | 84 | 6.2 | 0.027 | |||||||||||

| GIICL3 | 1120 | 4000 | 22,24 | 52 | 38 | 127 | 95 | 75 | 8 | 2 | 44 | 90 | 42 | 7.5 | 0.042 |

| 25,28 | 62 | 44 | 7 | 0.04 | |||||||||||

| 30,32,35,38 | 82 | 60 | 6.9 | 0.04 | |||||||||||

| 40,42,45,48,50,55 | 112 | 84 | 8.6 | 0.045 | |||||||||||

| GIICL4 | 1800 | 4000 | 38 | 82 | 60 | 149 | 116 | 90 | 8 | 2 | 49 | 98 | 42 | 10.1 | 0.08 |

| 40,42,45,48,50,55,56 | 112 | 84 | 12.2 | 0.089 | |||||||||||

| 60,63,65 | 142 | 107 | 14.5 | 0.098 | |||||||||||