Oilfield Solids Control Decanter Centrifuge in China

-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Shaanxi

-

Validity to:

Long-term effective

-

Last update:

2017-11-21 12:13

-

Browse the number:

272

+

Shaanxi Aipu Machinery Manufacture Co., Ltd.

- Contactaixin:

Ms. Jessie(Mr.)

-

Email:

telephone:

phone:

-

Arrea:

Shaanxi

Address:4th Rd. Jingyuan, Jinghe Industry Zone, Xi'an, China 710200

- Website:

+

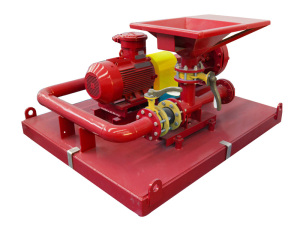

Decanter centrifuge principle:Drilling mud decanting centrifuge is the 4th phase solids control equipment. The drilling fluids will flow into drum via screw conveyor under high speed. Under drum and screw conveyor effect the solids will move along the drum wall radial direction. The particles will deposit on drum wall the small particles and liquid will be inside. There is also sediment area between drum internal wall and screw discharge. Drilling fluid after processed will flow out from big cone end. While the screw conveyor will push solids to drying area finally solids will be discharged out of small end. Usually there are low speed centrifuge, middle speed centrifuge and high speed centrifuge. They have different speed grade and the separation point will be different. But their principle are same

Application: Onshore and offshore oil&gas drilling, CBM exploration, HDD,waste management, etc. process system.

Issues affecting its performance: Medium size and shape, solids content or drilling mud property, drum size and shape, speed and separation factor, speed difference ratio

Main structure: Feed inlet, drum, screw conveyor, cover, gear box, main motor, control cabinet, base, support frame, discharge output, output groove.

Warning:

1)Please don't turn on centrifuge before installing belt cover

2)Rotate drum by hand confirm it is able to rotate freely before operation

3)Run the feeding pump before running centrifuge

4)Pay attention on rated speed and before drilling fluid flowing into centrifuge

5)Shut off the centrifuge when there is uncommon noise

6)Don't feed drilling fluid into centrifuge overload

7)If fluid to be processed is high viscosity please low down the feeding speed or dilution speed

8)Ensure fluid with barite at centrifuge inlet can return to tank for agitation

9)Stop feeding drilling fluid into centrifuge then stop dilution finally turn off the centrifuge

10)No moving, no opening cover during centrifuge running to avoid any failure or danger

11)The rotor speed can't exceed designed maximum speed to prevent breaking rotor. Replace the rotor regularly especially when there is corrosion on the rotor

Aipu Decanter centrifuge specification

Application: Onshore and offshore oil&gas drilling, CBM exploration, HDD,waste management, etc. process system.

Issues affecting its performance: Medium size and shape, solids content or drilling mud property, drum size and shape, speed and separation factor, speed difference ratio

Main structure: Feed inlet, drum, screw conveyor, cover, gear box, main motor, control cabinet, base, support frame, discharge output, output groove.

Warning:

1)Please don't turn on centrifuge before installing belt cover

2)Rotate drum by hand confirm it is able to rotate freely before operation

3)Run the feeding pump before running centrifuge

4)Pay attention on rated speed and before drilling fluid flowing into centrifuge

5)Shut off the centrifuge when there is uncommon noise

6)Don't feed drilling fluid into centrifuge overload

7)If fluid to be processed is high viscosity please low down the feeding speed or dilution speed

8)Ensure fluid with barite at centrifuge inlet can return to tank for agitation

9)Stop feeding drilling fluid into centrifuge then stop dilution finally turn off the centrifuge

10)No moving, no opening cover during centrifuge running to avoid any failure or danger

11)The rotor speed can't exceed designed maximum speed to prevent breaking rotor. Replace the rotor regularly especially when there is corrosion on the rotor

Aipu Decanter centrifuge specification

| Model | LW450x842N | LW450x1000N | LW600x1019N | GLW355x1258D-N | GLW450x1258D-N | GLW530x1320D-N |

| Drum Dia. | Φ450mm | Φ450mm | Φ600mm | Φ355mm | Φ450mm | Φ530mm |

| Drum Length | 842mm | 1000mm | 1019mm | 1258mm | 1258mm | 1320mm |

| Lambda Ratio | 1.9 | 2.2 | 1.7 | 3.5 | 2.8 | 2.5 |

| Drum Shape | Conical | Conical | Conical | Conical | Conical | Conical |

| Speed | 1800rpm | 2200rpm | 1500rpm | 3200rpm | 3000rpm | 2800rpm |

| Main Motor | 22KW | 30KW | 55KW | 30KW | 37KW | 55KW |

| Accessorial Motor | 5.5KW | 7.5KW | 11KW | 7.5KW | 11KW | 11KW |

| Max. Capacity | 40m³/h | 50m³/h | 60m³/h | 35m³/h | 60m³/h | 65m³/h |

| Separation Point | 5~7μm | 5~7μm | 5~7μm | 2~5μm | 2~5μm | 2~5μm |

| Separation Factor | 815G | 1215G | 705G | 2035G | 2250G | 1817G |

| Feeding Pump | 4KW(Submersible) | 5.5KW(Submersible) | 7.5KW(Submersible) | 7.5KW(Submersible) | 7.5KW(Submersible) | 7.5KW(Submersible) |

| Dimension | 2600×1550×1650 | 2750×1550×1700 | 2900×1600×1700 | 2900×1480×1650 | 2900×1550×1650 | 3300×1700×1750 |

| Weight | 2200kg | 2800kg | 3500kg | 3000kg | 3200kg | 4000kg |