NT-V60L Pin Type Horizontal Nano Sand Mill

-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Guangdong

-

Validity to:

Long-term effective

-

Last update:

2017-10-28 11:47

-

Browse the number:

44

+

Dongguan Longly Machinery Co., Ltd.

- Contactaixin:

Miss Kerry Hu(Mr.)

-

Email:

telephone:

phone:

-

Arrea:

Guangdong

Address:No. 8 Hongmian Rd, Xixi, Liaobu Town, Dongguan, Guangdong, China 523400

- Website:

+

Applications

Longly NTV Horizontal Beads Mill are designed for following Applicaton

(Suitable for 30nm~2micron Grinding)

Longly NTV Horizontal Beads Mill are designed for following Applicaton

(Suitable for 30nm~2micron Grinding)

| Ceramic Ink | Sublimation Ink | Inkjet Ink | Printing Ink | High Quality Paint | MLCC | Barium Carbonate |

| Barium Titanate | Ferrite | Pesticide | Pharmaceuticals | Cosmetics | Pigment | Food Additive |

| Zirconium Silicate | Aluminum Oxide | Zirconium Oxide | Kaolin | Battery Material | LFP | Lithium Titanate |

| Graphite | Carbon Nano Tube | Nano Thermal Insulation Coating | Nano Electronic Coating | Addictive | Electro-Paste | Nano Material |

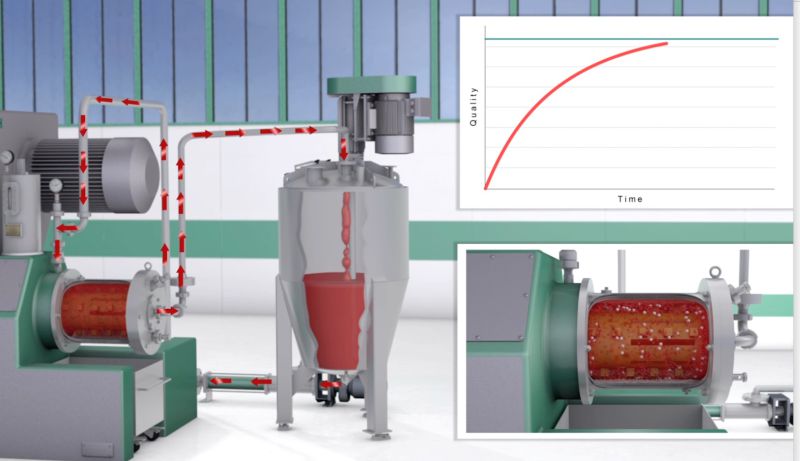

Why choose Longly NT-V Horizontal Bead Mill?

Longly NTV, are Designed for Your Profit( Large Flow Circulation Grinding System)

Technical Date

| Model | Volume of Grinding Chamber(L) | Motor Power(KW) | Output Capacity(L/h) | Media Size(mm) | Weight(kg) | Dimension(mm) |

| NT-V0.6 | 0.6 | 2.2 | 0.5-2 | 0.05-2.0 | 68 | 480*460*550 |

| NT-V1 | 1 | 3.7 | 0.6-4 | 0.1-2.0 | 120 | 520*460*620 |

| NT-V6 | 6 | 15 | 300 | 0.1-2.0 | 500 | 1300*710*1600 |

| NT-V10 | 10 | 22 | 500 | 0.05-2.0 | 1280 | 1430*860*1780 |

| NT-25 | 25 | 37 | 2000 | 0.05-2.0 | 1600 | 1830*950*1800 |

| NT-V30 | 25 | 45 | 2200 | 0.1-2.0 | 1800 | 1830*950*1850 |

| NT-V60 | 60 | 75 | ≥2500 | 0.2-2.0 | 3480 | 2230*1050*2200 |

| NT-V150 | 150 | 160 | ≥4000 | 0.2-2.0 | 6600 | 2900*1400*2600 |

| NT-V300 | 300 | 315 | ≥8000 | 0.2-2.0 | 9500 | 3700*1800*3200 |

| NT-V400 | 400 | 355 | ≥8000 | 0.3-2.0 | 11000 | 3800*1600*2850 |

General

The high-speed mill system Longly NT-V series with improved peg grinding system optimizes your production capacity, energy demand and quality. Designed for circulation operation and multi-pass operation, you achieve high throughput rates and high quality with a narrow particle size distribution for higher viscous products. A minimal control expenditure is necessary to guarantee highest reproducibility and save additional costs. The large dimensioned rotor with slotted pipe separation enables the use of very small grinding media of different materials. Special grinding chamber designs of ceramic are available for metal-free processing of your products.

Technique

- Peg grinding system with high volume specific power density of 2 kW/dm3

- Small length-/diameter proportion

- Designed for highest product throughputs (passage & circulation)

- Narrow residence time spectrum at lowest specific energy input

- Highly efficient centrifugal separation system

- Use of smallest grinding media (down to 90 µm)

- Exchangeable grinding chamber components of wear and corrosion resistant materials, adapted to your application

- Simple integration into production plants

- Applicable in a very wide viscosity range (from 20 mPas - 7000 mPas)

- Low product temperatures due to intensive cooling of the grinding tank and the agitator shaft

- Easy handling and process control

- Easy access to the separation system

- Grinding tank with lifting device

other products