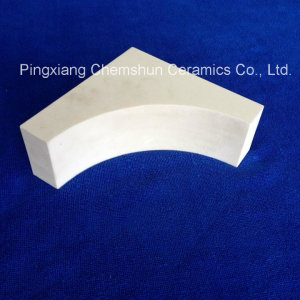

Abrasion Resistant Alumina Ceramic Cone Crushers Linings Applied to Quipment Protection

-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Jiangxi

-

Validity to:

Long-term effective

-

Last update:

2017-11-22 12:15

-

Browse the number:

310

+

Pingxiang Chemshun Ceramics Co., Ltd.

- Contactaixin:

Ms. Allen Yang(Mr.)

-

Email:

telephone:

phone:

-

Arrea:

Jiangxi

Address:Non-Metal Area of Shangliuyuan, Economic Development Zone, Pingxiang City, Pingxiang, Jiangxi, China 337000

- Website:

+

CHEMSHUN CERAMICS introduction :wear resistant ceramic lined cone

1: Chemshun wear resistant ceramic lined cone advantage :

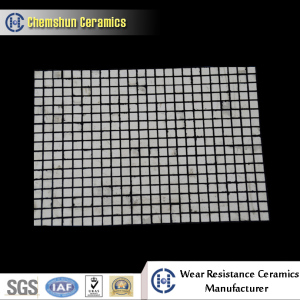

Engineering ceramic liner is different standard ceramic tile , designed and tailor-made with CAD

Software to suit any type of customer's components . Chemshun ceramcis offer a range of wear products that have been engineered to meet the most arduous, abrasive and high-impact duties experienced in a wide range of industries. Working intimately with customers,chemshun ceramics achieves extended asset life and operating cost reductions by the careful selection and application of wear resistant materials. In-house engineering, combined with years of on-site practical experience, enables to specify and design a comprehensive solution to any site wear problem.

3: Chemshun more ceramic lined equipment :

4: Technical data :

1) Chemical data :

2) Physical data :

1: Chemshun wear resistant ceramic lined cone advantage :

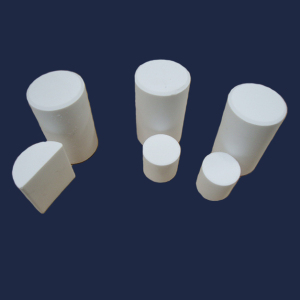

- Long lifetime and maintenance free operation

- NO operation interruption or production losses

- NO contamination of the conveyed materials due to abrasion, mixture or oxidation

- Physiologically harmless, suitable for food products

- Smooth surface to achieve good flowability and to avoid plugs

- No spilled material to clean up

Engineering ceramic liner is different standard ceramic tile , designed and tailor-made with CAD

Software to suit any type of customer's components . Chemshun ceramcis offer a range of wear products that have been engineered to meet the most arduous, abrasive and high-impact duties experienced in a wide range of industries. Working intimately with customers,chemshun ceramics achieves extended asset life and operating cost reductions by the careful selection and application of wear resistant materials. In-house engineering, combined with years of on-site practical experience, enables to specify and design a comprehensive solution to any site wear problem.

3: Chemshun more ceramic lined equipment :

4: Technical data :

1) Chemical data :

| Al2O3 | SiO2 | CaO | MgO | Na2O |

| 92~93% | 3~6% | 1~1.6% | 0.2~0.8% | 0.1% |

2) Physical data :

| Specific gravity (g/cc) | >3.60 |

| Apparent porosity (%) | 0 |

| Flexural Strength (20ºC, Mpa) | 280 |

| Compressive strength (20ºC, Mpa) | 850 |

| Rockwell hardness (HRA) | 80 |

| Vickers hardness (hv) | 1050 |

| Moh's hardness (scale) | ≥9 |

| Thermal Expansion (20-800ºC, x10-6/ºC) | 8 |

| Crystal Size (μm) | 1.3~3.0 |