CNC 3-Axis Glass Edging and Polishing Machine

-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Jiangsu

-

Validity to:

Long-term effective

-

Last update:

2017-08-22 10:47

-

Browse the number:

25

+

Changzhou Sinomac Machinery Technology Co., Ltd.

- Contactaixin:

Ms. Sophina(Mr.)

-

Email:

telephone:

phone:

-

Arrea:

Jiangsu

Address:No. 801, Changwu Road, Wujin High-Tech Zone, Changzhou, Jiangsu, China 213000

- Website:

+

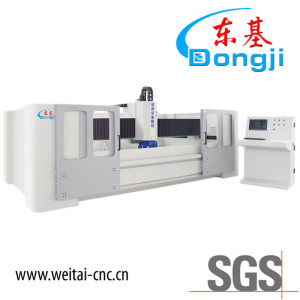

CNC 3-Axis Glass Edging and Polishing Machine

WT-M30(Single Spindle,Full-cover)

1.This machine is mainly used for grinding,edging,polishing and milling shaped flat glass after cutting.

2.The machine can process rectangular,round,oval and other irregular glass into that with flat,pencil,OG and other edges.

3.Rough grinding,fine grinding and polishing can be done in one operation.

4.Applied in auto glass,appliance glass,electronic glass,glass furniture and other shaped glass processing.

5.Glass sheet clamping on workbench by means of suction cups with different sizes,connected to vacuum pump for grinding,edging and polishing

Technical Parameters

Standard Edgwork Options

Technical Features

1.High bed rigidity-good stability

2. Precision ball screw-perfect accuracy

3.Standard vacuum suckers-perfect processing result

4.Double working stations-high speed,Capacity for mass production

5.Auto lubricating system-low consumption and long service life

6.The software and operator interface are easy to handle and the machine more convenient in maintenance and repairment.

Application Industry

Custom Service

1.Custom vacuum suction cups as per special glass shape

2.Custom machine size as per specific requirements of clients

3.Grinding wheel dressing device for fully utilizing wheels

4.Auto tool magazine for high efficiency and mass production

5.Conveyor device for transporting ultra-thin or large-size,heavy glass

6.Free glass test edging and process design are available

Why choose DONGJI?

1. 10 years glass edging machine manufacturing history, rich experience.

2. Delivery date:30-45days, prompt delivery.

3. SGS certified company, satisfying quality.

4. 20 plus machine models, more options upon request.

5. 1 year quality warranty policies , your best supplier.

Our service

1. One-year quality warranty for the whole machine.

2. 24-hours technical support by e-mail.

3. User-friendly English software, user manual and related videos

4. All spare parts for the machine provided

5. Face-to-face training or installation to the customer's factory by our professional service team

Our Patents

WT-M30(Single Spindle,Full-cover)

1.This machine is mainly used for grinding,edging,polishing and milling shaped flat glass after cutting.

2.The machine can process rectangular,round,oval and other irregular glass into that with flat,pencil,OG and other edges.

3.Rough grinding,fine grinding and polishing can be done in one operation.

4.Applied in auto glass,appliance glass,electronic glass,glass furniture and other shaped glass processing.

5.Glass sheet clamping on workbench by means of suction cups with different sizes,connected to vacuum pump for grinding,edging and polishing

Technical Parameters

| Glass Thickness | 0.7-30mm | Tool Attachment | BT40 |

| Max Bevel Width | 5mm | Electrospindle Power | 7.5kw |

| Bevel Angle | 0-45° | Max. Electrospindle Speed | 10000rpm |

| Axis Stroke(X,Y,Z) | 3000*1500*200mm | Electricity | 380V 50HZ,Custom |

| Table Size | 3000*1500mm | Total Power | 15kw |

| Positioning Accuracy | 0.005mm | Machine Size | 4500*2800*2200mm |

| Max. Processing Speed | 10m/min | Machine Weight | 5000kg |

Standard Edgwork Options

Technical Features

1.High bed rigidity-good stability

2. Precision ball screw-perfect accuracy

3.Standard vacuum suckers-perfect processing result

4.Double working stations-high speed,Capacity for mass production

5.Auto lubricating system-low consumption and long service life

6.The software and operator interface are easy to handle and the machine more convenient in maintenance and repairment.

Application Industry

Custom Service

1.Custom vacuum suction cups as per special glass shape

2.Custom machine size as per specific requirements of clients

3.Grinding wheel dressing device for fully utilizing wheels

4.Auto tool magazine for high efficiency and mass production

5.Conveyor device for transporting ultra-thin or large-size,heavy glass

6.Free glass test edging and process design are available

Why choose DONGJI?

1. 10 years glass edging machine manufacturing history, rich experience.

2. Delivery date:30-45days, prompt delivery.

3. SGS certified company, satisfying quality.

4. 20 plus machine models, more options upon request.

5. 1 year quality warranty policies , your best supplier.

Our service

1. One-year quality warranty for the whole machine.

2. 24-hours technical support by e-mail.

3. User-friendly English software, user manual and related videos

4. All spare parts for the machine provided

5. Face-to-face training or installation to the customer's factory by our professional service team

Our Patents