Automatic Rolling-Over Machine

-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Anhui

-

Validity to:

Long-term effective

-

Last update:

2017-12-20 18:18

-

Browse the number:

259

+

Anhui Innovo Bochen Machinery Manufacturing Co., Ltd.

- Contactaixin:

Mr. David He(Mr.)

-

Email:

telephone:

phone:

-

Arrea:

Anhui

Address:East to Wuyi Road, South to Zhongning Road Industrial Park, Mingguang City, Chuzhou, Anhui, China 322000

- Website:

+

Automatic rolling-over machine

With the high speed flute laminator using, and collect the paper automatically. Save time and effort, improve the production efficiency.

Performance: 1. Can be positive and negative paper receiver alternately

2. Paper stacking height between 1.6m-1.8m

3. The quantity of rolling-over according to paper thickness.

4. The speed is 4000-8000 sheet/hour. O

2

Operating principle:

Specification:

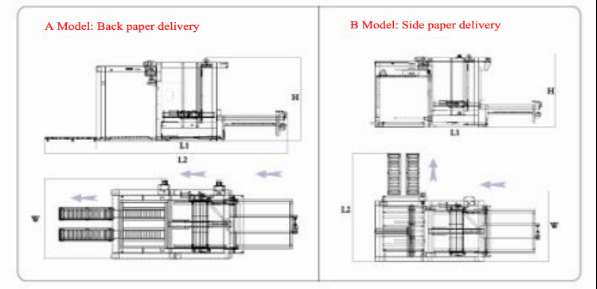

| Model | 1450*1250A | 1450*1250B | 1650*1650A | 1650*1650B |

| H | 2900 | 2900 | 3100 | 3100 |

| L1 | 4500 | 4950 | 6200 | 6400 |

| L2 | 6000 | 3500 | 7900 | 4600 |

| W | 2500 | 2500 | 3000 | 3000 |

| Max. size | 1450*1200 | 1450*1200 | 1650*1650 | 1650*1650 |

| Min. size | 500*500 | 500*500 | 600*600 | 600*600 |

| Power | 6.6kw | 6.6kw | 7.5kw | 7.5kw |

,1450 Technical parameters and configuration

1. Technical parameters

Max. paper size: 1450×1200 Min. paper size:500×500 Speed:6000sheet/hour

Max. power:2+7.5KW Net weight:1500kg

Machine size:4500×2500×2900(L×W×H)

Adaptive paper: According to the laminator

Ground rack;1200

2. Stardard Accessories

| NO | Description | Quantity | Remark |

| 1 | The main paper receiver station | 1part | |

| 2 | Deputy paper receiver station | 1part | |

| 3 | Air compressor | 1part | (According to your demand deploy --- central gas supply not deploy) |

| 4 | Ground rack | 1PCS | Motor paper delivery. If the space so small, pulling out the paper directly, so not supply. |

| 5 | Tray rack | 1PCS | Pulling out the paper directly, so not supply. |

| 6 | Slope | 2PCS | After paper out, oil pressure car pull paper using, pulling paper directly, deploy 1PCS. |

| 7 | Board:1200*1150 | 3PCS | Pulling paper directly, not deploy. |

| 8 | Tool cabinet | 1PCS | |

| 9 | Fixed plum wrench | 1SET | |

| 10 | Socket head wrench | 1SET | |

| 11 | "+","-" gimlet | Each 1 | |

| 12 | Hand grease gun | 1PCS | |

| 13 | Oil pot | 1PCS | |

| 14 | Operation instruction | 1PCS | |

| 15 | Inspection certificate of quality | 1PCS |

3. Machine configuration:

| NO | Description | Quantity | Remark |

| 1 | Brake Motors | CPG | |

| 2 | Air cylinder,solenoid valve | AIR TAC | |

| 3 | Contactor | Schneider | |

| 4 | Intermediate relay | Weidmuller | Germany |

| 5 | PLC | FATEK | Taiwan |

| 6 | Air switch | LG | Korea |

| 7 | Sensor | Omron | Japan |

| 8 | Air compressor | Xingbao |

4. Power meter

| NO | Description | Quantity | Remark |

| 1 | Tilt Motor | 1.5KW | |

| 2 | Lifting motor | 0.75KW | |

| 3 | Subsidies motor | 0.4KW | |

| 4 | Side beat paper adjustment motor | 90W | |

| 5 | Back beat paper adjustment motor | 90W | |

| 6 | Air compressor | 4KW | Optional |

,1650 Technical parameters and configuration

1. Technical parameters:

Max. paper size: 1650×1650

Min. paper size:600×600

Speed:6000sheet/hour

Max. power:6.6KW

Net weight:2500kg

Machine size:6200×2500×2900(L×W×H)

Adaptive paper: According to the laminator

(Ground rack:1650)

2. Stardard Accessories:

| NO | Description | Quantity | Remark |

| 1 | The main paper receiver station | 1part | |

| 2 | Deputy paper receiver station | 1part | |

| 3 | Air compressor | 1part | (Optional -central gas supply no match ) |

| 4 | Ground rack | 1PCS | Motor not send the paper |

| 5 | Tray rack | 1PCS | |

| 6 | Slope | 2PCS | After paper out, oil pressure car pull paper using. |

| 7 | Board :1650*1450 | 3PCS | |

| 8 | Tool cabinet | 1PCS | |

| 9 | Fixed plum wrench | 1SET | |

| 10 | Socket head wrench | 1SET | |

| 11 | "+","-" gimlet | Each 1 | |

| 12 | Hand grease gun | 1PCS | |

| 13 | Oil pot | 1PCS | |

| 14 | Operation instruction | 1PCS | |

| 15 | Inspection certificate of quality | 1PCS |

3. Machine configuration:

| NO | Description | Quantity | Remark |

| 1 | Brake Motors | CPG | |

| 2 | Air cylinder,solenoid valve | AIR TAC | |

| 3 | Contactor | Schneider | |

| 4 | Intermediate relay | Weidmuller | Germany |

| 5 | PLC | FATEK | Taiwan |

| 6 | Air switch | LG | Korea |

| 7 | Sensor | Omron | Japan |

| 8 | Air compressor | Xingbao |

4. Power meter

| NO | Description | Quantity | Remark |

| 1 | Tilt Motor | 2.2KW | |

| 2 | Lifting motor | 1.5KW | |

| 3 | Subsidies motor | 0.75KW | |

| 4 | One time paper feed motor | 400W | |

| 5 | Twice time paper feed motor | 400W | |

| 6 | Side beat paper adjustment motor | 90W | |

| 7 | Back beat paper adjustment motor | 90W | |

| 8 | Air compressor | 7.5KW | Optional |