Air Conveyor System, Air Conveying System for Powder

-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Shanghai

-

Validity to:

Long-term effective

-

Last update:

2017-12-27 17:40

-

Browse the number:

67

+

- Contactaixin:

Miss Jessie Zhao(Mr.)

-

Email:

telephone:

phone:

-

Arrea:

Shanghai

Address:No. 19 Fuqing Rd, Heqing. Pudong New District, Shanghai, China 201201

- Website:

+

1. conveying for powder

2. 0.5-50 t/h

3. The system is sealed and lead to few flying dust,

4. different raw material, suitable to conveying powders with various characters

Product Introduction of air conveyor sytem

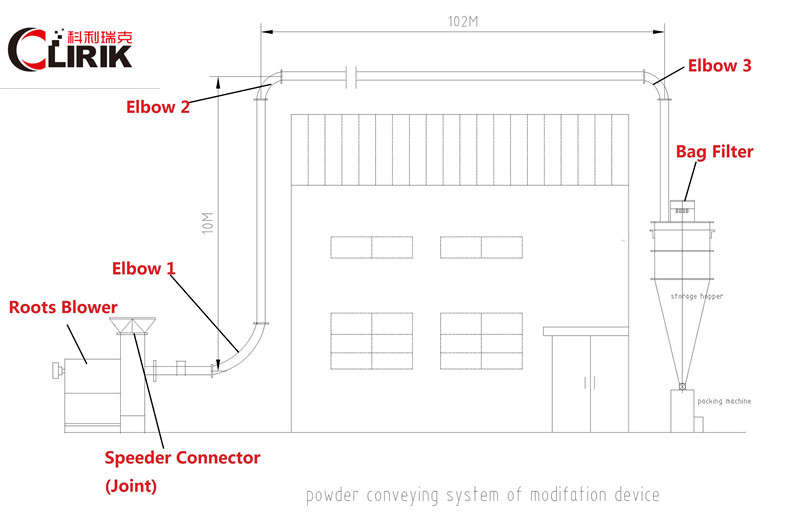

Air conveyor system, which takes Roots blower as the air source, is designed specifical for close distance and continuous transporting. Transporting distances is generally horizontal distance≤ 300m, vertical distance 30m. It is suit for conveying powder specific gravity ≤1.3, fineness≥60 mesh, moisture content≤5%, under the highest instantaneous temperature≤250°Cworking conditions, the maximum throughput is 60 t/h. It also can be used in the nesting conditions for single-point or multi-point requirements. The equipment is with long life, low operation and maintenance costs, small size, easy controlling, widely used in mining, building materials, coal, chemical and other industries.

Working principle of air conveying sytem:

Air conveyor sytem uses the principle of gas-solid flow fluidization, jet technology, combined with differential pressure principle, to finish this working progress. Taking the electric rotary feeder as the feeding device, the material evenly is put into the mixing chamber. At the same time, the Roots blower jet the high-speed air flow of materials into the acceleration chamber, the suspended flow into the conveying pipeline transport to in silos, according the separated by the feed gas, powder fall under silo gases into atmosphere, in order to achieve a powder material handling purposes.

Features of air conveyor sytem:

1. Variable arrangement of the pipe makes the production craft process more reasonable.

2.The system is sealed and lead to few flying dust, it benefit for environment protection.

3. Few movement parts, convenient maintenance, automatic control can be realized easily

4. High efficiency of transportation reduce the cost of packing, loading and unloading

5. Make the material avoid being damped, polluted, damaged, and mixed with other material, the quality of conveying is assured.

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china, as a pioneer enterprise, which is specializing in research, manufacture and sales of all kinds of grinding mill, all kinds of crushers from coarse grinding mill, fine grinding mill and ultra fine grinding mill, grinding mill related equipment, such as powder modifying machine, powder packing machine.powder conveying system, etc. We have devoted into grinding field for more than 30 years, we belive only focus can be professional.

Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

Please fill in your need products and your message and please do not forget mail and/or phone if you like to be contacted. We are the professional machine manufacturer in China with 30 years experience. Pls kindly check the following, in order to select a suitable machine, send you specific techinical data, quotation and the solution drawing for you.

1. What is the raw material do you want to convey?

2. What is the capacity per hour do you need?

3. What is the raw material input size?

4. What is the conveying length and height?

We hope you can tell us these details, we will give you the best quotation, technical data and solution drawing ASAP, thanks. Your satisfaction is our greatest pursuit, we would like to sincerely for your service! We look forward to your inquiry!

| Model | XLXB-75 | XLXB-100 | XLXB-150 | XLXB-200 | XLXB-250 |

| Capacity(t/h) | 1-4 | 3-9 | 10-15 | 15-20 | 18-25 |

| Blast capacity(m ³/min) | 3-9 | 9-20 | 20-36 | 36-50 | 50-70 |

| Inlet pipe diameter | ND100 | ND133 | ND125 | ND125/159 | ND273 |

| Velocity in pipe (m/s) | 13-16 | ||||

| pressure (kpa) | ≤98 | ||||

| body material | cast iron, cast steel, stainless | ||||

| motor | 3-15 | 15-30 | 35-65 | 70-90 | 90-110 |