Hba100-110130 Full Automatic Baling Machine for Tyre

-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Jiangsu

-

Validity to:

Long-term effective

-

Last update:

2017-11-09 15:47

-

Browse the number:

160

+

Nantong Sika Machinery Co., Ltd.

- Contactaixin:

Mrs. Summer Chen(Mr.)

-

Email:

telephone:

phone:

-

Arrea:

Jiangsu

Address:Xiezhuang Industrial Pack, Baipu Town, Rugao City, Jiangsu Province, P. R. China, Nantong, Jiangsu, China 226500

- Website:

+

1. Application:

This Baler is mainly used in the large supermarket, large and middle scope recycling stations and factories etc to press and loose materials into bales.

This series is suitable to press the waste paper, PET bottle, plastic flim, woven bag, straw, spong and zip-top can etc.

2.Technical Parameters:

3.Features:

Hydraulic Cylinders adjust size of output opening, safe and stable; easy to change the bale density.

Free to set the bale length, automatic record of bale number, making it convenient to calculate the production and cost.

Dencentralized knifes increases much the cutting efficiency and reduces the machine load.

Duplex-stage wire pushing system, high efficiency, and less space required for installation.

Automatic speed adjustment, increasing the production and decrease the consumption.

Pressure pre-set, overload protection, intelligent control and self-inspection program.

Independent emergency stop button to stop the machine at any time.

Auto micro-adjustment assembly method is used for hydraulic cylinders, reducing the torque and extending the service life.

4.Delivery: 30-45 days after receiving 30% deposite.

5.Service:

One year guarantee and lifelong maintenance.

Dimension drawing and foundation drawing are available.

Engineers are available to service and install the machine oversea for 3-5 days.

Provide some professional trainning for operation and maintenance.

If any problems in running, we provide solutions in 12 hours.

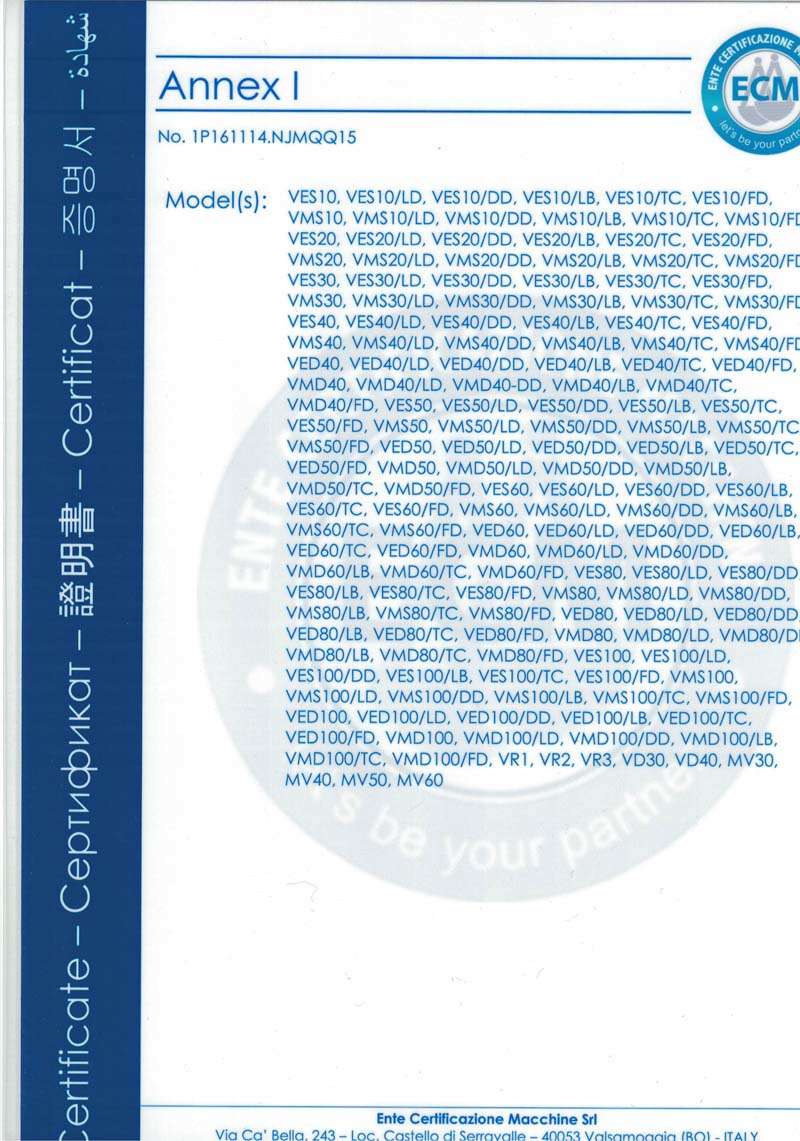

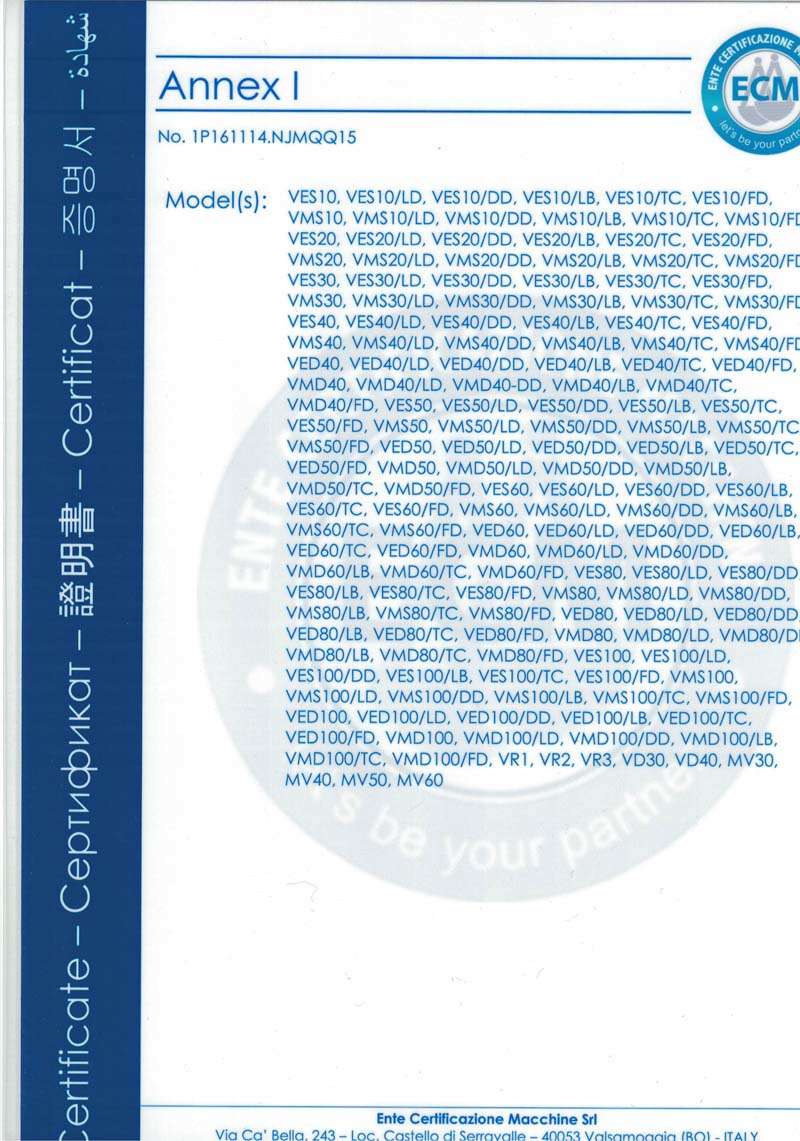

6.Certification

This Baler is mainly used in the large supermarket, large and middle scope recycling stations and factories etc to press and loose materials into bales.

This series is suitable to press the waste paper, PET bottle, plastic flim, woven bag, straw, spong and zip-top can etc.

2.Technical Parameters:

| Pressure of cylinder | 100 tons | |

| Main cylinder | YG220/160-2200 | Made by ourselves |

| Bale size | W1100×H1300×L(500~1800)mm | The length can be adjusted |

| Feed opening size | 1800×1020 mm(L×W) | |

| Cycle time | 16 s | Unload |

| Pressure of hydraulic cylinder | 18MPA | |

| Throughput | 6~9 tons / h | |

| Main motor power | 45 KW / 60 HP | Speed of revolution1440 r / min |

| Cooling hydraulic pump | CB-B80 | |

| Strapping mode | Full automatic | |

| Number of belting | 4 lines | |

| Wire size | ∮ 2.8 mm | |

| Feeding device | Conveyor or wind pipe | |

| Operation mode | Full automatic | Push button + touch screen |

| Voltage | 3P-200V/220V/380V/400V/415V-50/60Hz | The voltage can be customized |

| Control voltage | DC24V | |

| Oil reservoir | 1400 L | |

| Machine overall dimension | 10000mm×3700mm×3800mm(L×W×H) | Without conveyor |

| Machine weight | 14000 kg | |

| Conveyor width | 1.8 meters | |

| Conveyor length | 15 meters | |

| Conveyor power | 11KW | |

| Conveyor weight | 5.8 tons |

3.Features:

Hydraulic Cylinders adjust size of output opening, safe and stable; easy to change the bale density.

Free to set the bale length, automatic record of bale number, making it convenient to calculate the production and cost.

Dencentralized knifes increases much the cutting efficiency and reduces the machine load.

Duplex-stage wire pushing system, high efficiency, and less space required for installation.

Automatic speed adjustment, increasing the production and decrease the consumption.

Pressure pre-set, overload protection, intelligent control and self-inspection program.

Independent emergency stop button to stop the machine at any time.

Auto micro-adjustment assembly method is used for hydraulic cylinders, reducing the torque and extending the service life.

4.Delivery: 30-45 days after receiving 30% deposite.

5.Service:

One year guarantee and lifelong maintenance.

Dimension drawing and foundation drawing are available.

Engineers are available to service and install the machine oversea for 3-5 days.

Provide some professional trainning for operation and maintenance.

If any problems in running, we provide solutions in 12 hours.

6.Certification

other products